| 0 Comments | Ndulue Vincent

In the world of fleet management, monitoring fuel usage is crucial for maintaining efficiency, reducing costs, and preventing theft. Two essential tools in this domain are fuel level sensors and fuel consumption flow meters. Although they both deal with fuel monitoring, they serve distinct purposes and operate differently. In this blog post, we'll explore the differences between these two devices and their respective roles in fleet management.

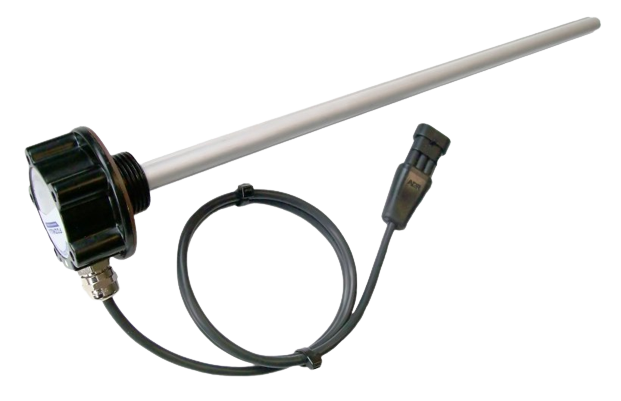

What is a Fuel Level Sensor?

A fuel level sensor is a device installed in a vehicle's fuel tank to measure the amount of fuel present at any given time. It provides real-time data on the fuel level, helping fleet managers monitor fuel usage and ensure that vehicles don't run out of fuel unexpectedly.

Types of Fuel Level Sensors:

-

Float-Type Sensors: These are the most common type, using a floating device that moves up and down with the fuel level. The position of the float is converted into an electrical signal, which is then displayed as the fuel level.

-

Capacitive Sensors: These sensors use the principle of capacitance, where the dielectric constant changes with the amount of fuel in the tank. This change is measured and converted into a fuel level reading.

-

Resistive Sensors: These sensors measure the resistance of a resistor that changes position as the fuel level changes. The resistance is then translated into a fuel level reading.

Advantages of Fuel Level Sensors:

- Real-Time Monitoring: Provides continuous data on fuel levels, enabling fleet managers to track fuel usage accurately.

- Prevents Fuel Theft: Alerts managers to sudden drops in fuel levels, indicating potential theft.

- Fuel Management: Helps in planning refueling schedules and avoiding unnecessary fuel stops.

What is a Fuel Consumption Flow Meter?

A fuel consumption flow meter measures the rate at which fuel is consumed by the engine. It provides data on the amount of fuel used over a specific period, allowing for detailed analysis of fuel consumption patterns. This information is critical for optimizing fuel efficiency and reducing operating costs.

Types of Fuel Consumption Flow Meters:

-

Positive Displacement Flow Meters: These meters measure the flow of fuel by capturing a known volume of fuel and counting the number of times this volume is filled. This data is then used to calculate the total fuel consumed.

-

Turbine Flow Meters: These meters measure the fuel flow rate by using a turbine that spins with the flow of fuel. The speed of the turbine is directly proportional to the flow rate, which is then used to calculate fuel consumption.

-

Coriolis Flow Meters: These meters measure the mass flow of fuel by detecting changes in the vibration of a tube caused by the flow of fuel. This method provides highly accurate measurements of fuel consumption.

Advantages of Fuel Consumption Flow Meters:

- Accurate Fuel Usage Data: Provides precise information on the amount of fuel consumed, helping fleet managers identify inefficient vehicles or driving habits.

- Optimization of Fuel Efficiency: Enables data-driven decisions to improve fuel efficiency and reduce costs.

- Maintenance Insights: Helps in identifying engine issues or malfunctions based on abnormal fuel consumption patterns.

Key Differences Between Fuel Level Sensors and Fuel Consumption Flow Meters

While both devices are crucial for fuel management, they serve different purposes:

-

Purpose:

- Fuel Level Sensor: Measures the current amount of fuel in the tank.

- Fuel Consumption Flow Meter: Measures the rate at which fuel is consumed by the engine.

-

Data Provided:

- Fuel Level Sensor: Provides real-time data on the fuel level.

- Fuel Consumption Flow Meter: Provides data on the total fuel consumed over a specific period.

-

Application:

- Fuel Level Sensor: Ideal for preventing fuel theft, monitoring fuel levels, and ensuring timely refueling.

- Fuel Consumption Flow Meter: Ideal for optimizing fuel efficiency, reducing costs, and diagnosing engine issues.

Conclusion

In fleet management, both fuel level sensors and fuel consumption flow meters play vital roles in ensuring efficient and cost-effective operations. Understanding the differences between these two devices allows fleet managers to implement the right tools for their specific needs, ultimately leading to better fuel management, reduced costs, and improved overall efficiency.

If you're looking to integrate these technologies into your fleet, it's essential to choose the right combination that suits your operational needs. With the right tools in place, you'll have the data you need to make informed decisions that drive your business forward.

0 comment(s) for "Understanding Fuel Level Sensors and Fuel Consumption Flow Meters: Key Differences and Applications"

Leave a Reply